Generic Drug Quality Standards: What the FDA Requires and How Testing Works

Jan, 26 2026

Jan, 26 2026

When you pick up a prescription for a generic drug, you’re not getting a lesser version of the medicine. You’re getting the same drug-just cheaper. But how does the FDA make sure that a $5 generic pill does exactly what the $50 brand-name version does? The answer isn’t simple, and it’s not just about matching ingredients. It’s about science, strict rules, and years of testing that most people never see.

What Makes a Generic Drug Really the Same?

The FDA doesn’t just say a generic drug is "the same." It proves it. Under the Hatch-Waxman Act of 1984, generic drugs must meet two key standards: pharmaceutical equivalence and bioequivalence.

Pharmaceutical equivalence means the generic has the exact same active ingredient, strength, dosage form (tablet, capsule, injection), and route of administration (oral, topical, etc.) as the brand-name drug. The label must list the same uses. That part is straightforward.

But here’s where it gets technical: bioequivalence. This is the real test. It means your body absorbs the generic drug at the same rate and to the same extent as the brand. If you take both pills, your blood should show nearly identical levels of the medicine over time. The FDA requires that the 90% confidence interval for two key measurements-Cmax (peak concentration) and AUC (total exposure)-must fall between 80% and 125% of the brand-name drug’s values. That’s not a guess. It’s a hard statistical rule.

For most small-molecule drugs like antibiotics or blood pressure pills, this is proven with a single-dose study in 24 to 36 healthy volunteers. Blood samples are taken over hours to map how the drug moves through the body. If the numbers line up within that 80-125% range, the FDA approves it.

How the FDA Tests Generic Drugs Before Approval

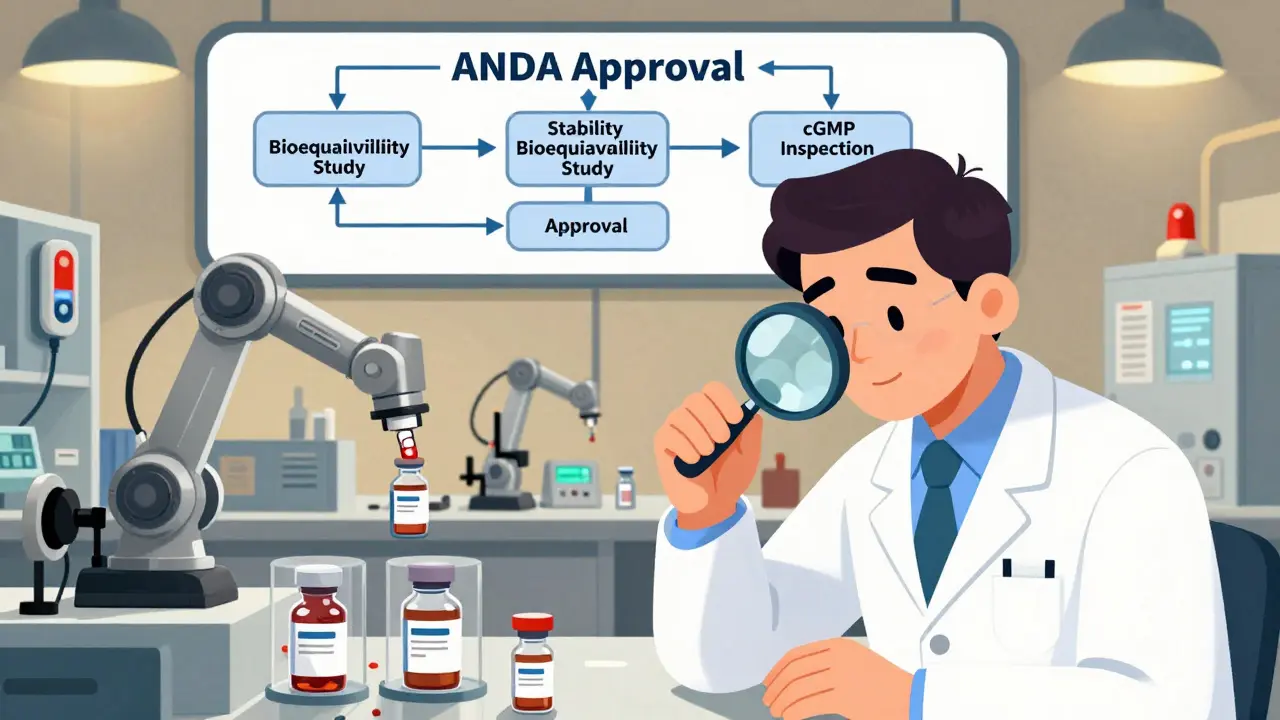

Before a generic drug hits the shelf, the manufacturer must submit an Abbreviated New Drug Application, or ANDA. It’s called "abbreviated" because it doesn’t need to repeat all the expensive clinical trials the brand-name company did. But that doesn’t mean it’s easy.

The ANDA includes:

- Proof of pharmaceutical equivalence

- Bioequivalence data from human studies

- Stability testing showing the drug won’t break down over its shelf life

- Details on manufacturing processes and quality control

Stability testing is especially critical. Manufacturers must run tests under harsh conditions-like 40°C and 75% humidity-for at least six months. They also track the drug under normal storage conditions for 12 to 24 months. If the active ingredient degrades too much, or if the tablet cracks or changes color, the application gets rejected.

Every batch of the drug must also pass lab tests for identity, strength, purity, and dissolution. That means the pill must break down in water at the same rate as the brand, so your body can absorb it properly. These tests use validated methods-no shortcuts.

Manufacturing Rules Are Just as Strict

It doesn’t matter how good the science is if the pill is made in a dirty factory. That’s why the FDA enforces Current Good Manufacturing Practices (cGMP), written into federal law under 21 CFR Parts 210 and 211.

These rules cover everything:

- How raw materials are received and stored

- How equipment is cleaned and calibrated

- How workers are trained

- How every step of production is documented

There’s no "good enough" here. If a manufacturer skips a step or doesn’t record a temperature reading, the entire batch can be thrown out. The FDA inspects over 3,500 facilities each year-many of them in India, China, and other countries. One out of every three inspections finds serious violations.

And here’s something most people don’t know: about half of all generic drugs in the U.S. are made by the same companies that make the brand-name versions. Sometimes, they’re even made in the same factory, just on a different line. The FDA doesn’t treat them differently. A pill made by Pfizer for its own brand and a pill made by Pfizer for a generic are held to the same standard.

Complex Drugs Are a Bigger Challenge

Not all drugs are created equal. Simple pills? Easy to copy. But what about inhalers, injectables, topical creams, or patches? These are called complex generics. They don’t just need the same chemical. They need the same physical structure, particle size, viscosity, and delivery mechanism.

For these, bioequivalence studies using blood levels often aren’t enough. The FDA has created over 2,143 product-specific guidances to help manufacturers prove "Q3 sameness"-meaning the generic matches the reference drug in quality, performance, and characteristics. For example:

- For an asthma inhaler, they test how fine the mist is and how much of it actually reaches the lungs.

- For a topical cream, they measure how deeply the drug penetrates the skin.

- For long-acting injectables, they look at how slowly the drug releases over weeks.

In 2022, the FDA found that 17% of complex generic applications needed more than standard testing. That’s why they’ve invested $15.7 million into new research and held 18 public workshops with scientists and manufacturers to solve these problems.

Real-World Results: Do Generics Work?

Over 90% of prescriptions filled in the U.S. are for generic drugs. And they’ve saved the healthcare system $37 billion in 2022 alone. But do they actually work?

A 2022 Consumer Reports survey of 1,200 Americans found 89% were satisfied with generics. Most people never notice a difference.

But there are exceptions. Some drugs have a narrow therapeutic index-meaning the difference between an effective dose and a toxic one is very small. Levothyroxine, used for thyroid conditions, is one of them. A 2021 study in JAMA Internal Medicine found that 12.3% of patients who switched between different generic versions had to adjust their dose because their thyroid levels shifted.

On Reddit’s r/pharmacy thread, 1,427 people shared their experiences. 83% said they saw no difference. The 17% who did mostly mentioned issues with seizure medications or blood thinners like warfarin. These are high-risk drugs. That’s why some doctors still prefer to keep patients on the same brand or generic version consistently.

The FDA and the American Medical Association both agree: approved generics are safe and effective. But they also say consistency matters. If you’re on a narrow-therapeutic-index drug, stick with the same manufacturer if you can.

How Long Does Approval Take?

Getting a generic drug approved isn’t quick. The standard review time for an ANDA is 10 months. But many applications get rejected on the first try. In 2022, the FDA issued 478 complete response letters-meaning the application wasn’t approved and needed more data. Only 892 were approved that year.

Why so many rejections? Often, it’s because the manufacturer didn’t provide enough data on stability, manufacturing controls, or bioequivalence. Sometimes, the facility failed inspection. The FDA doesn’t rush this. A single approval can take years of back-and-forth.

Since 2012, the Generic Drug User Fee Amendments (GDUFA) have sped things up by giving the FDA more funding and staff. Today, the Office of Generic Drugs has 750 people reviewing applications. They’re not just checking paperwork-they’re reading scientific studies, reviewing lab data, and sometimes even visiting factories.

Why Generics Cost So Much Less

Generics aren’t cheaper because they’re lower quality. They’re cheaper because the manufacturer didn’t pay for the original research. Developing a new drug can cost over $2 billion. Generics skip that step. They only pay for proving equivalence and building a clean, compliant factory.

That’s why generics make up only about 23% of total prescription drug spending in the U.S.-but fill over 90% of prescriptions. They’re the backbone of affordable healthcare.

And the market is growing. In 2022, the U.S. generic drug market was worth $135.7 billion. By 2027, it’s projected to hit $180.3 billion. More people are choosing generics. More insurers are pushing them. And the FDA is working harder than ever to make sure every pill you take is safe, effective, and exactly what it says it is.

Are generic drugs as safe as brand-name drugs?

Yes. The FDA requires generic drugs to meet the same strict standards for safety, strength, quality, and purity as brand-name drugs. They must prove bioequivalence-meaning your body absorbs them the same way. Thousands of inspections and millions of doses are monitored every year. The American Medical Association and the FDA both confirm that FDA-approved generics are safe and effective.

Can I switch between different generic versions of the same drug?

For most drugs, yes. But for drugs with a narrow therapeutic index-like levothyroxine, warfarin, or certain seizure medications-switching between different generic brands can sometimes cause small changes in blood levels. If you’re on one of these, talk to your doctor. Some pharmacists will keep you on the same manufacturer unless you ask for a change. Consistency matters more with these drugs.

Why do some generic pills look different from the brand?

By law, generics can’t look exactly like the brand-name drug because of trademark rules. That’s why color, shape, and scoring might be different. But the active ingredient, strength, and how it works in your body are identical. The differences are only in inactive ingredients like dyes or fillers, which don’t affect the drug’s performance.

Are all generic drugs made in the U.S.?

No. Many generic drugs are made in India, China, and other countries. But the FDA inspects all facilities-domestic and foreign-that supply drugs to the U.S. About 50% of generic drugs are made by the same companies that make brand-name versions, sometimes even in the same factories. The FDA holds all of them to the same cGMP standards.

How does the FDA know a generic drug will last until its expiration date?

Manufacturers must submit stability data showing the drug remains effective and safe under real-world conditions. This includes testing at high heat and humidity for six months, plus long-term studies for 12-24 months. The FDA reviews this data before approval and can request additional testing if they have concerns. Every batch must also meet quality specs before it’s released.

Timothy Davis

January 27, 2026 AT 11:05The FDA’s 80-125% bioequivalence range is a joke. I’ve seen generics that make me feel like I’m on a different drug entirely-especially with SSRIs. The math might check out in a lab, but bodies aren’t test tubes. And don’t get me started on the fillers-some generics use lactose or dyes that trigger reactions in sensitive people. The FDA doesn’t test for that. They test for blood levels. That’s it.

fiona vaz

January 27, 2026 AT 23:27It’s reassuring to know how much rigor goes into this. I used to worry about generics until I read this. The stability testing alone-40°C and 75% humidity? That’s intense. It’s not just about saving money; it’s about making sure the medicine doesn’t turn to dust on the shelf. Kudos to the FDA team working behind the scenes.

Sue Latham

January 28, 2026 AT 00:11Ugh, don’t even get me started on generics. My cousin’s on levothyroxine and switched brands and ended up in the ER with palpitations. Like, how is that okay? The FDA says it’s fine, but if your thyroid’s acting up and your doctor’s like ‘eh, it’s the same pill,’ that’s not science-that’s negligence. Also, why do they look like cartoon pills? I feel like I’m swallowing a Pez.

John Rose

January 28, 2026 AT 06:15Interesting breakdown. I’m curious about the dissolution testing-how exactly do they simulate gastric conditions? Is it just distilled water at 37°C, or do they use simulated gastric fluid with enzymes and pH buffers? The FDA’s guidance documents are surprisingly detailed on this, but most patients have no idea what’s involved. It’s not magic-it’s analytical chemistry.