FDA Foreign Facility Inspections: What Overseas Food Plants Must Now Do to Stay Compliant

Nov, 20 2025

Nov, 20 2025

What Foreign Food Facilities Need to Know About FDA’s New Inspection Rules

Every year, the U.S. imports about 15% of its food supply from overseas. That’s more than $180 billion worth of products-from fresh produce and seafood to supplements and packaged snacks-coming from over 300,000 registered foreign facilities. And since 2024, the FDA has changed how it checks them.

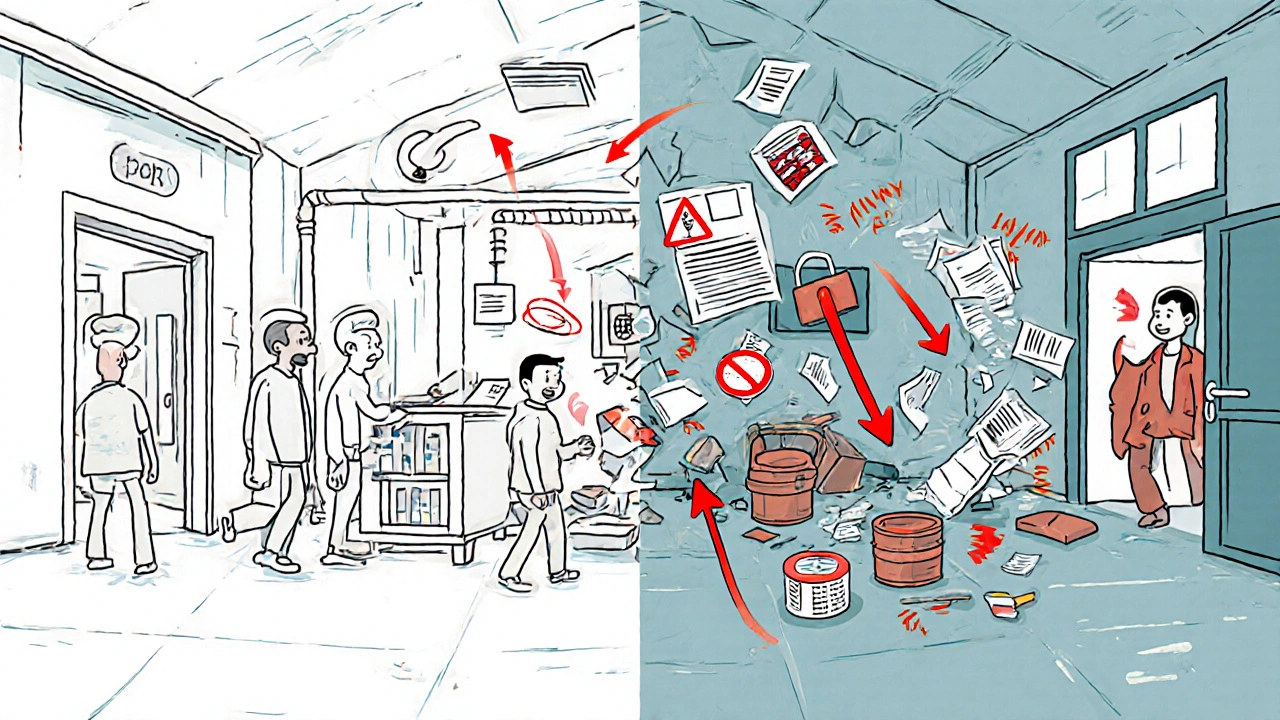

For decades, foreign food plants got advance notice before FDA inspectors showed up. They had time to clean up, train staff, print documents, and hire translators. Meanwhile, U.S. factories were inspected without warning. That double standard is over.

Starting in May 2024, the FDA began conducting unannounced inspections at foreign facilities, just like it does at home. No more calls saying, “We’ll be there next Tuesday.” No more time to hide problems. If you export food to the U.S., your facility must be ready to open its doors at any moment-day or night, holiday or weekday.

Why the FDA Changed Its Approach

The shift wasn’t random. It came after years of warnings from inspectors and watchdog groups.

In 2018, ProPublica found that FDA inspections of foreign food plants had dropped to their lowest levels in decades. Budget cuts meant inspectors were flying less, and many facilities went years without being checked. At the same time, global supply chains got more complex. A single batch of spices could pass through five countries before landing on a U.S. shelf. One contaminated shipment could trigger a nationwide recall.

The FDA’s own data showed that foreign facilities had higher refusal rates than U.S. ones. Products were being turned away at U.S. ports because of unsanitary conditions, mislabeled ingredients, or missing safety records. The agency realized: if you only inspect when you’re invited, you’re not seeing what really happens.

“We’re ending a double standard,” said FDA Commissioner Martin A. Makary in May 2024. “American manufacturers don’t get a heads-up. Foreign ones shouldn’t either.”

The goal? Make sure every product entering the U.S. meets the same safety rules-no matter where it was made.

How the FDA Picks Which Facilities to Inspect

The FDA doesn’t inspect every foreign plant every year. There are too many. So they use a risk-based system to decide who gets visited-and when.

Three things matter most:

- What you make. Raw seafood, sprouts, and baby formula carry higher risk than canned beans or bottled water. High-risk products get priority.

- How you make it. Processes that involve raw ingredients, temperature control, or cross-contamination risks (like mixing allergens) are watched more closely.

- Your track record. If your facility has had products refused entry before-if the FDA has blocked your shipments for safety issues-you’re on the list. Repeat offenders get bumped to the top.

Under the Food Safety Modernization Act (FSMA), the FDA was required to double foreign inspections every year for five years after 2011. While progress stalled during budget cuts, the agency has since ramped up again. In 2023, inspectors visited over 5,000 foreign facilities. The target? To reach 10,000 by 2026.

What Happens During an Unannounced Inspection

When an FDA inspector walks into your facility without warning, they’re not there to chat. They’re there to find problems.

Here’s what they check:

- Are your workers washing hands and wearing proper gear?

- Are your equipment and surfaces cleaned and sanitized between batches?

- Do you have records showing temperature logs, supplier approvals, and allergen controls?

- Can you immediately pull up production records from the last 90 days?

- Are your storage areas dry, pest-free, and labeled correctly?

Inspectors can take photos. They can review digital files. They can ask to watch your production line in real time. And they can demand access to any record-even if it’s stored on a server in another country.

One major rule: no hospitality. Since 2024, FDA inspectors are forbidden from accepting rides, meals, or hotel stays from your company. They pay for their own lodging and transport. This isn’t about being rude-it’s about avoiding any appearance of favoritism.

What Gets You in Trouble (and How to Avoid It)

Many foreign facilities think they’re safe if they don’t have major contamination. But the FDA can shut you down for paperwork issues alone.

Here are the top five violations that lead to import refusals or criminal charges:

- Delaying or denying access. If you tell inspectors they can’t enter a room, or you lock a door during inspection, that’s a violation of the Federal Food, Drug, and Cosmetic Act.

- Redacting records. Covering up names, dates, or batch numbers on documents? That’s illegal. Even partial redactions can trigger enforcement.

- Limiting observation. If you say, “You can’t watch us mix the sauce,” or “We don’t let visitors near the packaging line,” you’re breaking the rules.

- Interrupting production. Turning off machines or pausing lines just to “clean up” during an inspection counts as obstruction.

- False registration. If your facility’s FDA registration says you make organic juice, but you’re actually producing raw meat, you’re committing fraud.

These aren’t just fines. The U.S. Department of Justice can pursue criminal charges. That means your company could face fines, asset seizures, or even debarment from exporting to the U.S. forever.

How to Prepare-Without Knowing When They’ll Come

You can’t predict when the FDA will show up. But you can make sure your facility is always ready.

Here’s what top-performing foreign facilities do:

- Keep digital records live and searchable. Use cloud-based systems so inspectors can access logs from anywhere. Don’t rely on paper files in a locked drawer.

- Hire bilingual staff permanently. Don’t wait for an inspection to call a translator. Have someone on-site who speaks English and understands FDA terminology.

- Run monthly mock inspections. Pretend the FDA is coming. Have your quality team walk through every step. Find the gaps before they do.

- Train everyone-not just managers. Cleaners, packagers, and drivers need to know what to do if an inspector asks questions. A single misstatement can raise red flags.

- Review your FDA registration every year. Make sure your facility’s listed products, processes, and contact info are current. Outdated info = automatic refusal.

One facility in Vietnam that exports herbal supplements started doing weekly internal audits after their first refusal in 2023. Within six months, their approval rate jumped from 68% to 97%.

What If You Get Refused Entry?

Getting a shipment blocked is stressful-but not the end.

If the FDA refuses your product at the border, you’ll get a written notice explaining why. Common reasons: missing certificates, unsanitary conditions, or undeclared allergens.

You have two options:

- Reprocess or repackage. If the issue is fixable (like a mislabeled label), you can fix it and resubmit.

- Export it elsewhere. If you can’t fix it, you’ll have to ship it to another country.

But here’s the catch: if you get three refusals within five years, your facility will be placed on the FDA’s “Import Alert” list. That means every future shipment gets automatically detained. You’ll have to prove you’ve fixed the problem before even one box is allowed in.

Getting off the list takes months-and a full re-inspection.

Who’s Doing It Right

Some countries have adapted faster than others.

Facilities in India and China that export high-value products-like pharmaceuticals, organic foods, and infant formula-are leading the way. Many now have full-time FDA compliance officers on staff. They use AI tools to flag potential issues in their records before inspections happen.

Small family-run farms and low-volume exporters are struggling. They don’t have the budget for digital systems or full-time staff. The FDA acknowledges this gap but says the rules apply to everyone. There’s no exemption for size.

That’s why industry groups are pushing for FDA-approved third-party inspectors. The idea? Let trusted local auditors do preliminary checks, then let the FDA spot-check them. The FDA is testing this model-but it’s not official yet.

The Bigger Picture: Global Food Safety

The FDA isn’t alone in tightening rules. The EU, Japan, and Canada have all increased their oversight of foreign suppliers.

But the FDA remains the most aggressive. Why? Because the U.S. market is huge. And consumers expect safety.

For foreign manufacturers, the message is clear: if you want to sell in the U.S., you need to operate like you’re in America. No shortcuts. No excuses. No advance notice.

It’s not about fear. It’s about trust. The FDA wants to know that when you say your product is safe, you mean it-every day, not just when someone’s watching.

Frequently Asked Questions

Do I need to register my foreign facility with the FDA?

Yes. All foreign facilities that manufacture, process, pack, or hold food for U.S. consumption must register with the FDA every two years. Registration includes a signed certification that you allow FDA inspections under the FD&C Act. Failure to register means your products will be denied entry at the border.

Can the FDA inspect my facility without my permission?

Yes. Under the Federal Food, Drug, and Cosmetic Act, FDA inspectors have legal authority to enter and inspect foreign facilities that export to the U.S. You cannot refuse entry. Denying access is a federal offense and can lead to import refusals, fines, or criminal charges.

What if I don’t have an English-speaking staff member?

You must provide a qualified translator during inspections. The FDA does not provide translators. If you can’t produce one on the spot, the inspection may be delayed or terminated, and your facility could be flagged for refusal. Many facilities now hire bilingual quality assurance staff full-time to avoid this risk.

How often will the FDA inspect my facility?

There’s no fixed schedule. High-risk facilities with past violations may be inspected annually. Low-risk facilities might go several years without a visit. But unannounced inspections can happen at any time, regardless of your last inspection date.

Can I appeal an FDA inspection finding?

You can respond to an inspection report and submit corrective actions, but you cannot appeal the inspection itself. If the FDA issues a refusal, you can request a re-inspection after fixing the issues. If your facility is placed on an Import Alert, you must submit extensive documentation and pass a follow-up inspection to get removed.

What Comes Next

The FDA plans to keep tightening its grip. By 2026, it aims to use AI to predict which facilities are most likely to fail inspections. It’s also testing digital inspection tools that let inspectors upload photos, videos, and data in real time from overseas.

Third-party audits may become part of the system-but only if they meet strict FDA standards. For now, the message is simple: be ready. Always.

If you export food to the U.S., your facility isn’t just a factory. It’s a checkpoint in the American food supply chain. And the FDA isn’t asking for cooperation anymore. They’re requiring compliance.

Nicholas Swiontek

November 21, 2025 AT 14:26Robert Asel

November 22, 2025 AT 08:00Shannon Wright

November 23, 2025 AT 17:43vanessa parapar

November 23, 2025 AT 23:55Ben Wood

November 25, 2025 AT 10:12